We have worked on many projects, and have decided to give you an idea of the process we go through to finalize a project.

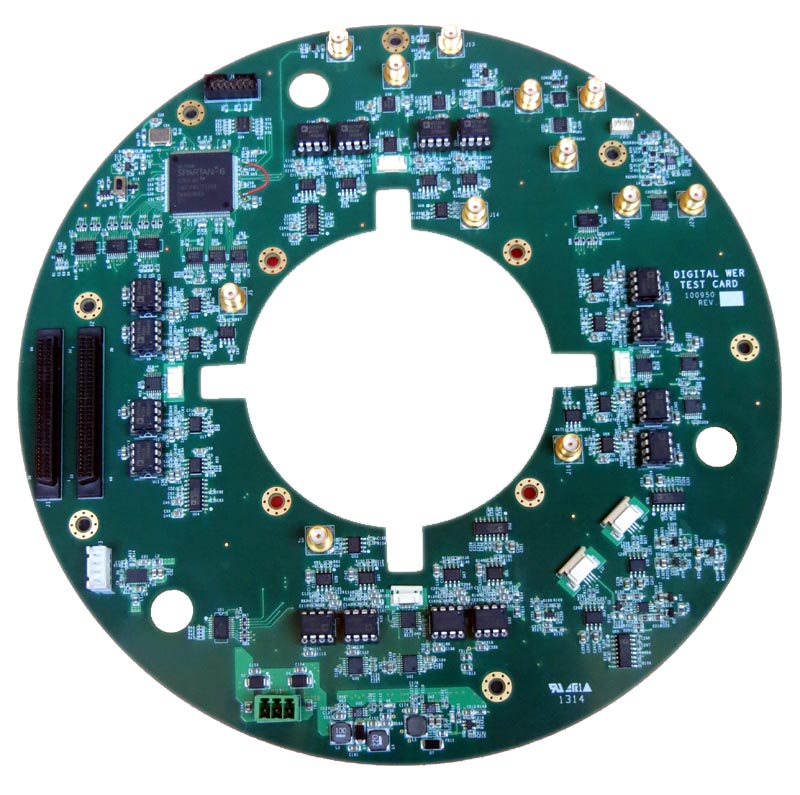

The Digital WER Test card that we have designed is a highly complex, wide function card, which:

- is a test card for an IC maker

- is an 8 layer board, with controlled impedance

- contains almost 1000 components including FPGA

Such a project takes long time to design and finalize. This is how long each step of the project took us:

- Schematic design: 3 weeks (with multiple iterations and reviews)

- PCB layout: 2 weeks

- PCB fabrication: 1 week

- PCB assmelby: 1 week

- First article Bring-up: 1 week

- The Initial FPGA load (verilog) (done during bring-up): 1 week

- After the initial run, there were 3 more production runs.

Our customer received:

- Schematic diagram

- Bill of materials

- Gerber files

- Fabrication drawing

- Assembly files

- Assemlby drawings

- First working board and programming instructions

- Bit file for FPGA and the verilog source code

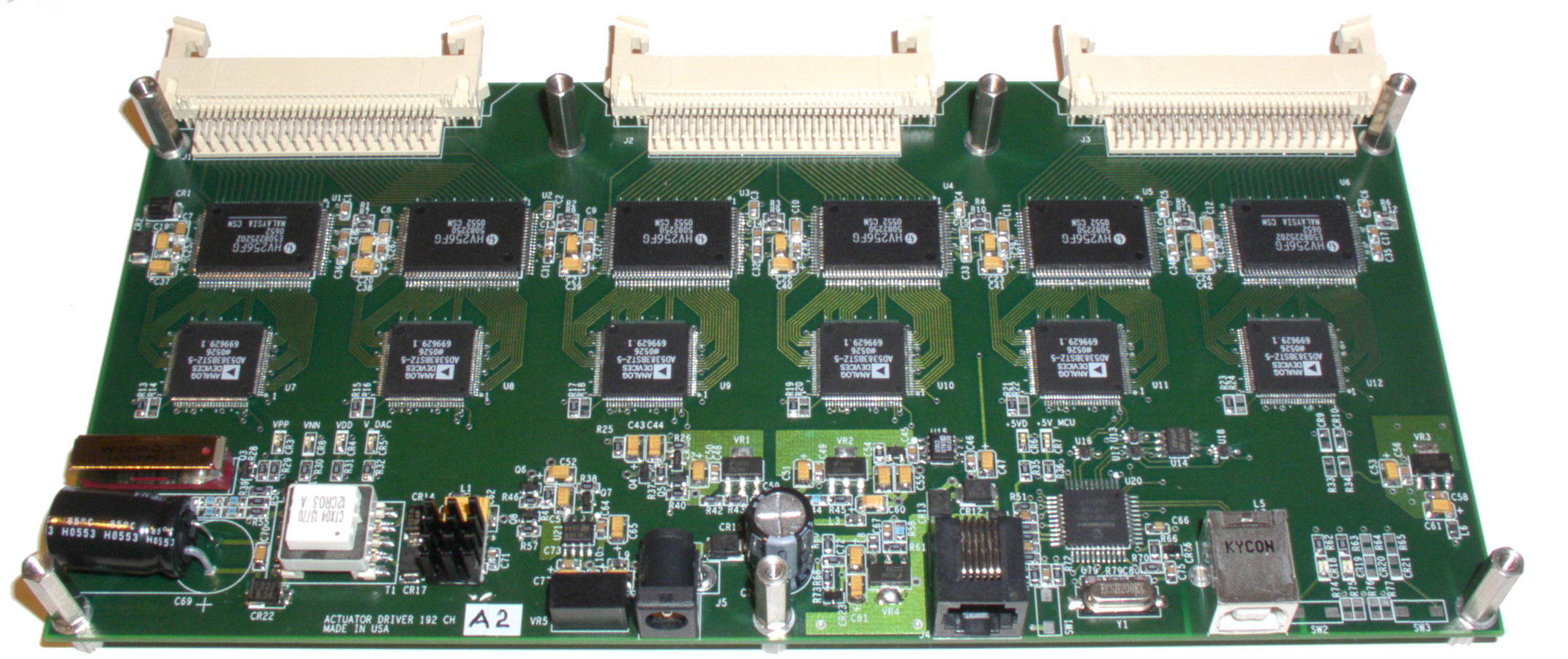

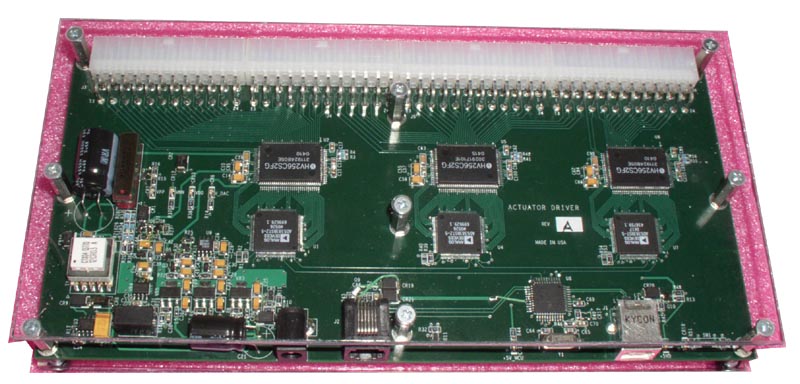

Similar to Actuator Driver but has 192 output channels

Layout, mechanical design and enclosure design. Multiple iterations between this plug-in module and motherboard, schematic, mechanical and layout in order to fit everything. For PCB RF material Rogers 4004 has been used to allow operation up to 6GHz. Enclosure - milled 6061-T6 aluminum. Design time - 2 weeks.

Some features of this project:

- 96 independent output channels.

- Single 12VDC power input.

- onboard 300VDC power supply.

- 0-300VDC output for each channel with 12 bit resolution and current limiting feature.

- USB connection to a PC.

- PCB - 4 layers.

Design time - 6 weeks, including PCB manufacturing and shipping.